Do you have construction projects that require a complete lot of drilling? Then, you must have the tools which can be right the job, along with CGE GROUP's product 8 inch core drill bit. Perhaps one of the most crucial tools you must have in your toolbox may be the 95mm core drill bit. This little bit of equipment can be an innovative and tool safe can enable you to get the task done quickly and effortlessly. Read on to find out more in relation to the numerous benefits, innovative features, safety measures, applications, and quality about the 95mm core drill bit.

The 95mm core drill bit has a few benefits that make it a vital tool in any construction project, the same as 3 core drill bit supplied by CGE GROUP. Firstly, it offers a drilling high, therefore you can have the task done quickly. Secondly, it is durable, and you do not have to change it out as often as other drill bits. Thirdly, it has a drilling accurate that guarantees your holes are consistent and accurate. Finally, it is created for use in various materials, that means it is a tool versatile any construction project.

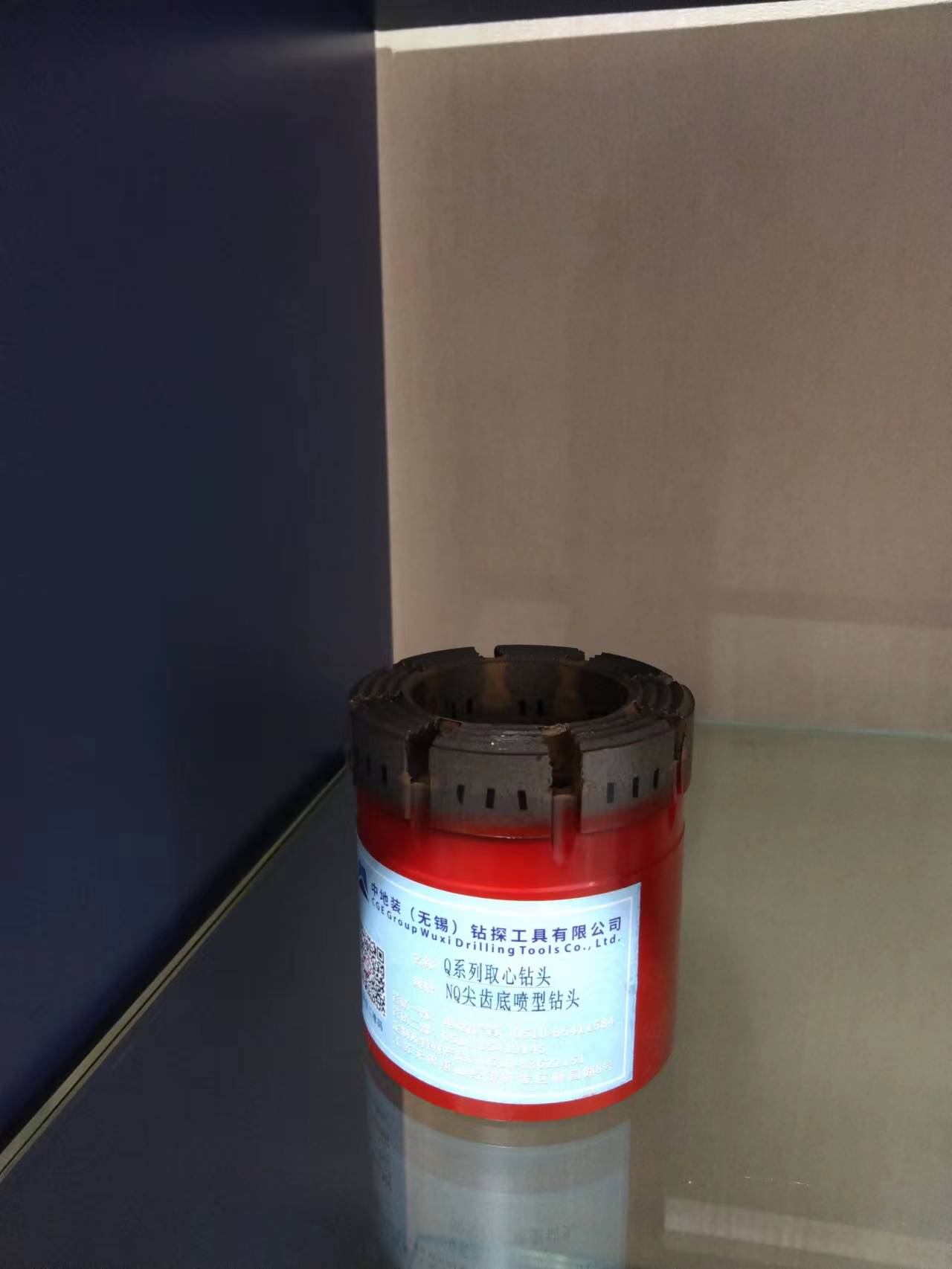

The 95mm core drill bit is an innovative tool that has been intended to make your drilling experience efficient and safe, also the CGE GROUP's product such as 4 core drill bit. The bit is fitted with an diamond-tipped advantage a high level of hardness, that means it is tough and durable. Moreover it has a unique design facilitates fast and effective cooling, which reduces the possibility of overheating. Furthermore, the bit has a removable pilot drill that can be changed whenever it becomes blunt, which helps you save the cost of purchasing a new bit.

Safety is vital in any construction project, and the 95mm core drill bit was made with safety in brain, similar to the core drill bit for steel developed by CGE GROUP. The bit has a shank that works with most drills and has a anti-slip design assures a firm grip on the drill. Furthermore, the bit has an integral water feed system offering you with a constant flow of water to your leading edge, which reduces the risk of the bit fire getting.

Using the 95mm core drill bit is straightforward and simple, the same as CGE GROUP's 8 core drill bit. Firstly, ensure that the drill and the bit are compatible. Secondly, connect the bit to the drill firmly and securely. Thirdly, start drilling at a slow speed while applying gentle pressure. As the bit cuts through the material, boost the drilling gradually speed and pressure. Lastly, make sure that you utilize the bit with the suggested drilling speed and apply water to the edge cutting lessen the risk of overheating.

Most of production equipment and raw materials imported from abroad, as well being 95mm core drill bit. Additionally business has employees who have more 15 years extensive production experience, from mechanical equipment operators, who ensure stability and quality of our goods. The quality and evaluation of products also top-of-the-line China. To date, it a faithful and steady customers both across globe and China.

It was founded 1958 and a reputable manufacturer drilling equipment in China. It relocated Wuxi Huishan Economic Development Zone May 2008 and covered area of 120mu, with assets 200m. The company holds variety independent intellectual property rights patents and regularly updated the domestic small diameter deep hole drilling data, and also participated the development of national standard Geological Core Drilling Tools. The company ISO9001:2000 95mm core drill bit, OHSAS18000 occupational, health, and safety management system certification, and API-5CT certification American Petroleum Association.

We a well-established company with history of field geological exploration. To meet needs of different customers we provide range of business models including 95mm core drill bit, retail and customized processing. We can offer customers appropriate production equipment design solutions and high-quality goods that suited to the on-site and production needs different customers. Our company provides wide variety of customised product solutions which include demand analysis, selection products as well on-site studies along with construction safety, as well operating specifications. We can provide you an all-in-one plan service for exploration geological areas and raw materials.

It a business owned by state with many years tradition. The company employs staff of more 20 research and development design engineers. Each engineer over 95mm core drill bit in R and D for products and equipment. They able to design and build professional equipment and products suit customer requirements.

The 95mm core drill bit is of exceptional quality and is made to withstand the rigors associated with the construction industry, along with the metal core drill bit built by CGE GROUP. The bit is constructed of high-quality materials, which ensures reliability and durability. Also, it undergoes several quality checks that you get a high-quality and effective tool before its released in to the market, which guarantees.

The 95mm core drill bit is acceptable for drilling through various materials, including concrete, brick, and masonry. It is, therefore, ideal for usage in construction jobs such as drilling holes for electrical cables, pipes, and other installations. Furthermore, it can be used in renovations, repairs, and upkeep work.

The 95mm core drill bit is an innovative, safe, and versatile tool a must-have in any construction project, just like the CGE GROUP's product called 3 core drill bit. Its several benefits, innovative features, safety measures, and applications ensure it is a tool essential the toolbox of any constructor or home owner. When used properly, you can be assisted due to it complete your drilling jobs effortlessly, quickly, and accurately. Moreover, purchasing the tool from a reputable provider will guarantee you are getting a high-quality and beneficial tool.